- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Esperanto

- Català

- שפה עברית

- Cymraeg

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Twi

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Tǝlam Kanuri

- Punjabi

- پښتو

- Chichewa

Ɔkwan bɛn so na wobɛhwɛ ahu sɛ nsɔano no yɛ adwuma wɔ butterfly valves mu?

2025-05-29

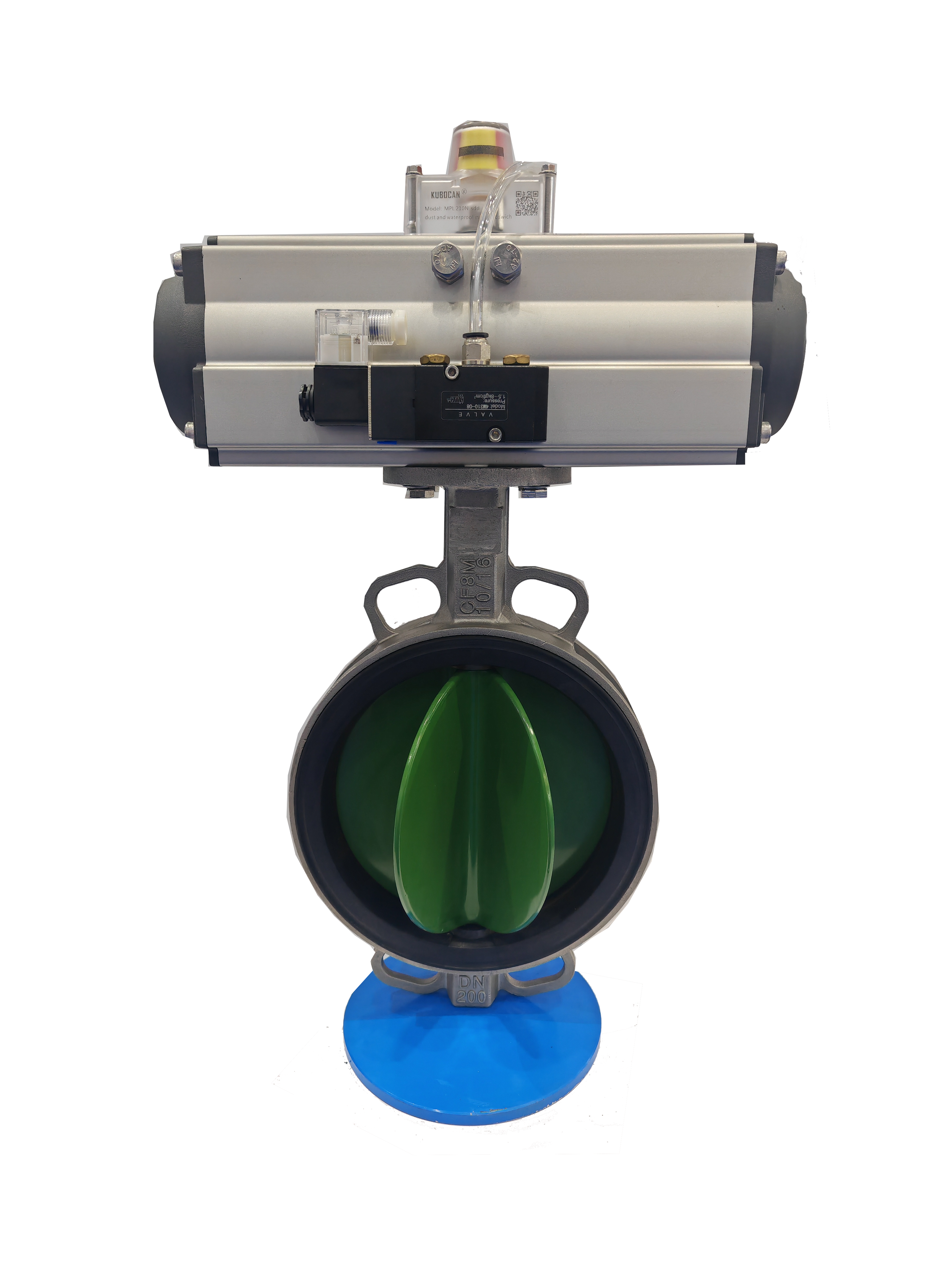

Wɔ mfiridwuma mu nsuo afiri nhyehyɛeɛ ahodoɔ mu no, wɔde ntontom valve di dwuma kɛseɛ wɔ nsuo sohwɛ tebea mu ɛnam sɛ ɛyɛ ketewa, ɛbue ntɛmntɛm na ɛto mu, na ɛnyɛ den sɛ ɛbɛyɛ adwuma nti. Nsɔano adwumayɛ, a ɛyɛ ntontom valve ahorow no dwumadi titiriw no mu biako no, fa adwumayɛ mu mmɔdenbɔ, ahobammɔ ne ahoɔden a ɛwɔ nsu afiri nhyehyɛe no mu no ho tẽẽ. Ɛnyɛ sɛ nsɔano pa betumi asiw nsu a ɛbɛtwetwe no ano nko, na mmom ɛbɛtrɛw valve no nkwa nna mu na ama ɛka a wɔbɔ wɔ nsiesie ho no so atew. Enti, ɔkwan bɛn so na wobetumi ahwɛ ahu sɛ nsɔano adwumayɛ a ɛwɔ butterfly valves mu? Eyi hwehwɛ sɛ wotumi di so yiye fi nkitahodi ahorow pii te sɛ nea wɔayɛ, nneɛma a wɔpaw, nea wɔde yɛ, nea wɔde si hɔ ne ne siesie mu.

1. Structural Design yɛ nea wogyina so yɛ nsɔano adwumayɛ .

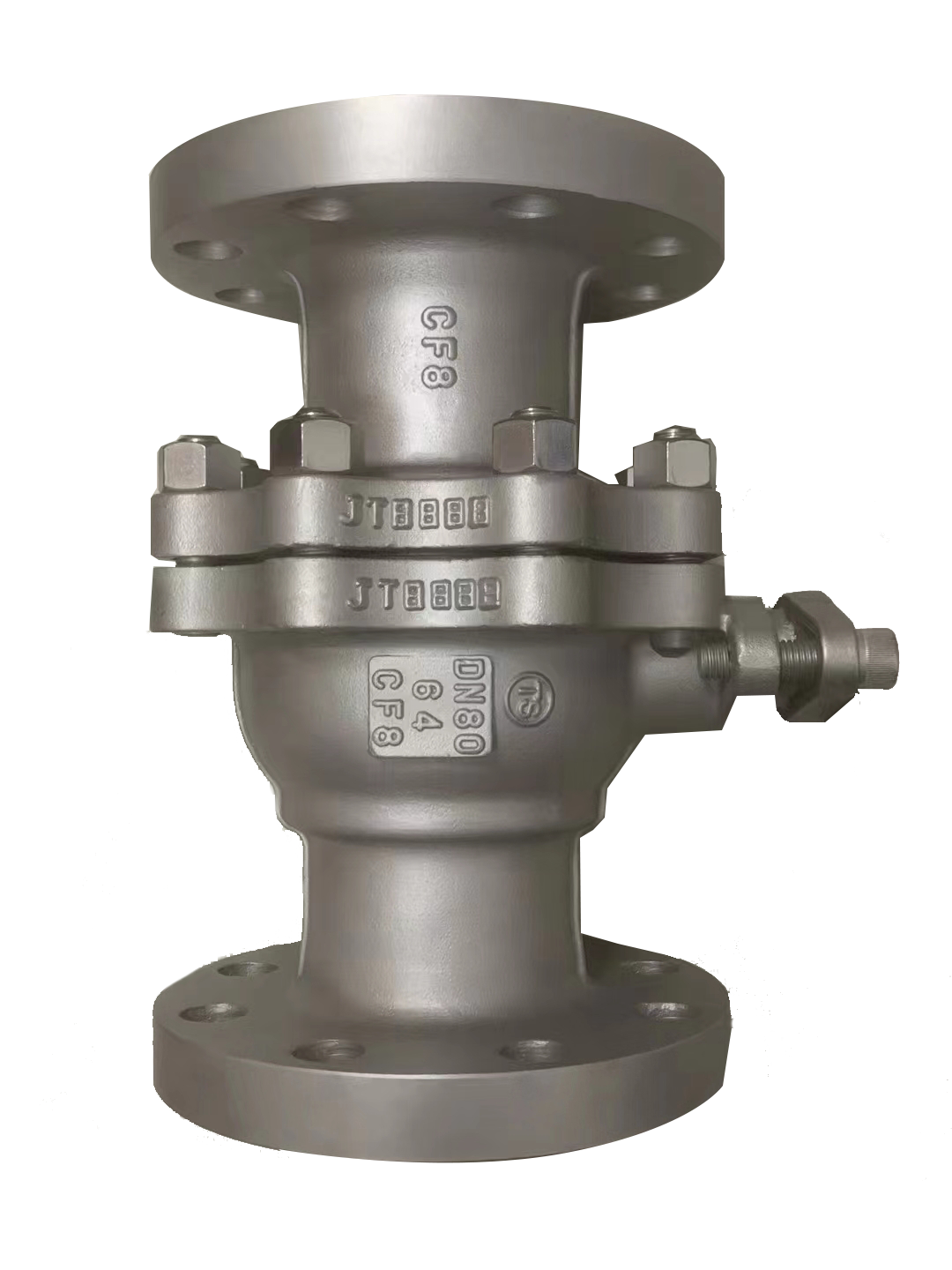

Nsɔano titiriw abien na ɛwɔ hɔ a .Nwansena valve ahorow ., biako yɛ soft sealing structure na biako nso yɛ metal sealing structure. Nwansena valve a ɛyɛ mmerɛw a wɔde hyɛ mu no taa de nneɛma a ɛyɛ den te sɛ rɔba ne polytetrafluoroethylene di dwuma, a ɛwɔ nsɔano tumi pa, a ɛfata ma ɔhyew ne nhyɛso tebea a ɛfata. Metal sealing butterfly valves fata ma ɔhyew a ɛkɔ soro, nhyɛso a ɛkɔ soro anaasɛ corrosive media, nanso ɛwɔ ahwehwɛde a ɛkorɔn ma dwumadie pɛpɛɛpɛ ne nneɛma a ɛyɛ adwuma.

Wɔ structure design mu no, sealing pair a ɛne ntontom valve ahorow no hyia no ho hia kɛse. Fit a ɛwɔ sealing surfaces, contact angle, ne force distribution ntam no bɛka sealing effect no. Enti, wɔ nhyehyɛe no mfiase no, ɛho hia sɛ wosusuw nneɛma te sɛ medium no su, adwumayɛ nhyɛso, ɔhyew nsakrae, ne nea ɛkeka ho ho yiye, sɛnea ɛbɛyɛ a wɔbɛpaw nsɔano nhyehyɛe a ɛfata ne nneɛma a wɔde ka bom.

2. Nneɛma a ɛkorɔn ne ade titiriw a ɛma wotumi de nsɔano a wotumi de ho to so di dwuma .

Nneɛma a wɔpaw no yɛ link titiriw foforo a ɛbɛma wɔahwɛ ahu sɛ sealing performance. Wɔ ntontom valve a ɛyɛ mmerɛw a wɔde hyɛ mu no ho no, wɔtaa de rɔba, EPDM, NBR, PTFE ne nneɛma afoforo na ɛyɛ nkaa a wɔde hyɛ mu no. Saa nneɛma yi wɔ elasticity pa ne corrosion resistance, na ebetumi akura resilience ne sealing tebea pa mu wɔ bere tenten a wobue ne nea wɔde to mu no mu.

ma dade a wɔde akata so .Nwansena valve ahorow ., dade nneɛma a ahoɔden wom kɛse te sɛ dade a ɛnyɛ den ne carbide a wɔde simenti ayɛ ho hia. Ɛnyɛ ɔhyew ne nhyɛso a ɛkɔ soro nko na saa nneɛma yi tumi gyina ano, na mmom ɛyɛ nea ɛko tia ɔporɔw a emu yɛ den nso. Titiriw bere a ɛde nsɛm a ɛyɛ mmerɛw kɛse anaasɛ nneɛma nketenkete a ɛyɛ den di dwuma no, dade a wɔde hyɛ mu no tumi yɛ adwuma tebea a ɛyɛ den kɛse.

Ɛfata sɛ yɛhyɛ no nsow sɛ ɛsɛ sɛ nneɛma a wɔde hyɛ mu a wɔpaw no ne adwumayɛ tebea pɔtee no hyia. Ɛsɛ sɛ wɔsɔ ɔhyew a ɛko tia, onyin a ɛko tia, corrosion resistance, ne nea ɛkeka ho no hwɛ yiye na wontumi nyɛ no generalized.

3. Mfiridwuma ho nimdeɛ a wɔde yɛ adwuma no nya nea ɛfata a ɛwɔ sealing surface no so no so nkɛntɛnso .

Sɛ mpo nhyehyɛɛ no yɛ nea ntease wom na nneɛma no yɛ nea ɛkorɔn a, wontumi nnya nsɔano adwumayɛ pa sɛ nea wɔyɛ no pɛpɛɛpɛ no nyɛ nea ɛfata a. Ɛsɛ sɛ wɔyɛ nsɔe a ɛwɔ ntontom valve no so no ho adwuma pɛpɛɛpɛ na wɔyam na ama ayɛ mmerɛw na ayɛ petee. Wɔ nneɛma a wɔyɛ ankasa mu no, nsensanee nketenkete, burrs anaasɛ deviations a ɛwɔ sealing no so no betumi abɛyɛ asiane a ahintaw a ɛbɛma nsu a ɛretu no akɔ mu.

Titiriw ma dadeɛ-sealed butterfly valves, mfiridwuma ho nimdeɛ a wɔhwehwɛ no yɛ den kɛseɛ. Ɛsɛ sɛ wɔde sealing ring ne valve seat no yɛ pɛpɛɛpɛ pɛpɛɛpɛ na ama wɔatumi asiw ano denneennen na ɛyɛ den. Bio nso, concentricity adjustment a ɛwɔ nhyiamu dwumadie no mu no nso ho hia yie paa sɛ ɛbɛhwɛ sɛ valve disc no wɔ gyinabea a ɛfata bere nyinaa wɔ sealing surface no so berɛ a worebue na woretoto mu na woakwati were anaasɛ leakage ɛnam offset nti.

4. Nsiesiei a ɛteɛ no hwɛ hu sɛ nsɔano nhyehyɛe no nsɛe .

Ɛnyɛ ade no ankasa nko na nsɔano adwuma a ɛwɔ ntontom valve no mu, na mmom ɛne nea wɔde si hɔ no wɔ abusuabɔ kɛse. Wɔ instɔlehyɛn mu no, ɛho hia sɛ wɔhwɛ hu sɛ flanges a ɛwɔ pipeline no ne valve no mu no yɛ petee na bolts no yɛ pɛpɛɛpɛ. Sɛ installation no nni hɔ a, sealing ring no betumi ayɛ pɛpɛɛpɛ anaasɛ mpo ne fã bi asɛe, na ɛnam so asɛe mfitiase nsɔano nhyehyɛe no.

Sɛ ɔde ntontom valve a ɛyɛ mmerɛw a wɔde ahyɛ mu no rehyɛ mu a, ɛsɛ sɛ nea ɔde di dwuma no de n’adwene si so titiriw sɛ ebia baabi a nsɔano nkatabo no wɔ no ahyɛ valve no nipadua ne valve disc no mu koraa anaa. Sɛ wɔde butterfly valve a wɔde dade ayɛ a wɔde hyɛ mu no rehyɛ mu a, ɛsɛ sɛ wɔhwɛ hu sɛ nsonsonoe anaa ɔkwan biara nni valve no mu bere a wɔato mu no. Nhyɛso sɔhwɛ akyi a wɔde ahyɛ mu no yɛ ɔkwan titiriw a wɔfa so hwɛ sɛ nsɔano no yɛ adwuma.

5. Nsiesiei a wɔyɛ no daa na amma nsɔano anyin na asɛe .

ɛmfa ho sɛnea ɛyɛ papa no .Butterfly valve .IS, ehia sɛ wosiesie no daa na wɔhwɛ mu. Bere a bere kɔ so na medium no sɛe no, ade a wɔde hyɛ mu a ɛyɛ mmerɛw no betumi anyin, apaapae, ne nea ɛkeka ho, na aka nea wɔde hyɛ mu no. Saa bere yi de, ɛsɛ sɛ wɔsesa sealing ring no wɔ bere ano na amma nhyehyɛe no ankɔ anaasɛ ɔhaw nketenkete de ba.

Ɛwom sɛ dade a wɔde kyekyere ntontom valve no yɛ nea ɛtra hɔ kyɛ de, nanso ebetumi nso ayɛ adwuma bere a wɔayɛ no bere tenten akyi. Titiriw wɔ frequency a ɛkɔ soro a ɛbue ne nea ɛto mu anaasɛ nneɛma nketenkete a ɛyɛ den wɔ medium no mu no, sealing surface no taa sɛe kakra. Ɛdenam hwɛ a wobɛhwɛ sɛnea nsɔano no awie daa na woayam no yiye so no, wobetumi atrɛw ntontom valve no mu nkwa nna mu na wɔatumi akura nsɔano no adwumayɛ mu.

Nsɔano adwumayɛ a ɛwɔ .Butterfly valve .ne core guarantee ma ne stable adwumayɛ wɔ adwumayɛ tebea a ɛyɛ den mu. Efi structure design, material selection, precision machining, to installation, commissioning ne akyiri yi nsiesie, link biara wɔ nkɛntɛnso tẽẽ wɔ sealing effect no so. Sɛ wɔretɔ na wɔde ntontom valve nneɛma redi dwuma a, ɛnsɛ sɛ nnwumakuw no hwɛ nneɛma no ankasa yiye nko, na mmom ɛsɛ sɛ wɔde wɔn adwene si sɛnea wɔhwɛ so yiye ne sɛnea wɔhwɛ so bere a wɔde redi dwuma no so.

Ɛnam nyansahu mu paw, adwumayɛ a ɛyɛ pɛpɛɛpɛ ne sohwɛ a ɛkɔ so so no, ɛnyɛ sɛ ntontom valve ahorow no tumi nya nsu a wɔde di dwuma yiye nko, na mmom ɛma wonya ahotoso a ɛyɛ den ma nhyehyɛe no nyinaa adwumayɛ a ahobammɔ ne ahoɔden wom nso. Eyi ne ade titiriw a ɛma wodi nneɛma pa ne ahotoso akyi wɔ mfiridwuma ho adwuma biara mu.

Nsɛm a ɛfa ho .

- Dɛn ne check valve atirimpɔw?

- Ɔkwan bɛn so na wobɛpaw low temperature environment gate valve?

- Sɛ gate valve no kɔhyɛ bere a wɔde di dwuma no mu a, dɛn na ɛsɛ sɛ meyɛ?

- Dɛn nti na wɔansɔ aponkɛse no mu nsu a ɛwɔ mu no ano yiye?

- Bere tenten bɛn na wɔde siesie ntontom valve ahorow no?

- Ɔkwan bɛn so na wobɛpaw anyinam ahoɔden ntontom valve?

New Products